- Home

- Company Strength

In Changsheng, we have an advanced manufacturing and inspection system to guarantee the quality of our electricity control devices, all of which have been certified by UL, VDE, KC, CE, and CQC. Currently, the market share of our thermal protector in China has reached 60-70%. Our products are exported to many regions and countries such as the United States, the European Union, the United Kingdom, Brazil, Argentina, Mexico, Russia, Ukraine, Thailand, Japan, and South Korea.

Warehouse for raw material

Core materials like bimetal strip and gasket are especially introduced from Japan and America. Different materials are sorted and stored in the defined regions, marked with different color labels to show the incoming date and ensure first in first out.

Incoming inspection

Our quality inspectors will conduct various tests for materials’ properties such as the hardness and resistivity of the bimetallic strip, and the wires’ flame retardancy, aging property, elongation, and tensile strength, etc.

Energy dispersive fluorescence spectrometer

EDX-720 energy dispersive fluorescence spectrometer from Shimadzu is utilized to test whether the materials are in line with the environmentally friendly standards. It is able to take high-definition images of the tested parts. The detection precision reaches 0.1ppm.

Bimetallic strip punching

The punching line for bimetallic strip features a production capacity of 560/min. In this process, the deviation of temperature is controlled within ±3℃. With the welding and assembly operation conducted automatically, the production efficiency is improved by 30%, and the pass rate is increased for 20%.

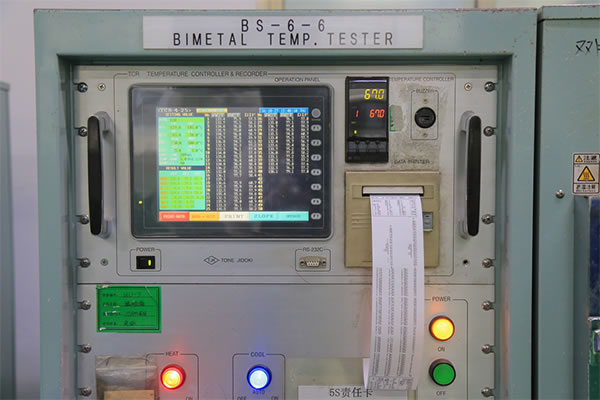

Opening and closing temperature check

The temperature detector from Japan allows for a testing accuracy of ±0.5℃. Operators can input or change the parameters through the touch screen, which displays the tripping temperature, the resetting temperature, the difference between tripping and resetting temperature, the max temperature, the min value, and the average value. CPK value is showed on the screen and can be printed automatically.

17AM-D Production Capacity and Process Control

17AM-D monthly capacity is around 6 million pieces with 5 automatic production lines. PLC is equipped with every welding machine and assembly machines. When the welding current or voltage is out of the rated range, the welding power supply will send a signal to the PLC, which will then transfer it to the control cylinder and the product will be judged as unqualified and sorted-out. 100% opening and closing temperature calibration and NG sorting-out is conducted.

Laboratory

According to the motor parameters, we will have some experiments to determine the optimal thermal protection and control solutions. All of the tests including the high and low temperature test, the hot and cold impact test, the vibration test, and the life test are conducted in our laboratory.