- Home

- Company Strength

At Changsheng, we are proud of our advanced manufacturing and inspection systems, allowing us to guarantee the top quality of our electricity control devices. Further proving our quality, every single one of our products has been certified to UL, VDE, KC, CE, and CQC standards. Our market share for thermal overload relays in China is 60 to 70%, and our products are sold to loyal customers all over the world, including the United States, Europe, Brazil, Argentina, Mexico, Russia, the Ukraine, Thailand, Japan and South Korea.

Raw Material Warehouse

Core materials such as the bimetal strip and gasket are imported from Japan and the United States, and are then sorted and stored according to region. Different colored labels indicate the incoming date, ensuring the first products received are the first to be used, guaranteeing raw material quality.

Incoming inspection

Our quality inspectors carry out different tests to determine material properties, including the hardness and resistivity of the bimetallic strips, and flame resistance, aging, elongation and tensile strength of wires.

Energy dispersive fluorescence spectrometer

Our EDX-720 energy dispersive fluorescence spectrometer is from Shimadzu, and is used to ensure materials all meet environmentally friendly industrial standards. It is capable of taking high definition images of tested parts, with a detection precision of 0.1ppm.

Bimetallic strip punching

The punching line for our bimetallic strip features a production capacity of 560 pieces/minute. During this process, the temperature deviation is maintained within ±3°C. The production efficiency has also seen an improvement of 30%, due to the automatic welding and assembly operations. This automation has also allows for a 20% increase in the pass rate.

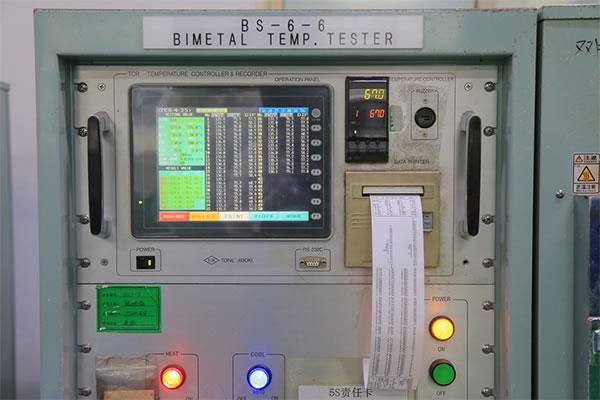

Opening and closing temperature check

Our temperature detector was imported from Japan, and features a testing accuracy of ±0.5℃. Operators can easily change or set parameters using the touch screen, on which the tripping temperature, reset temperature, difference between the tripping and reset temperatures, maximum temperature, minimum value, and average value are displayed. The CPK value is also displayed on the screen, and can be printed off automatically.

17AM-D Production Capacity and Process Control

The monthly capacity of the 17AM-D is about 6 million pieces, produced using 5 automatic production lines. Each welding and assembly machine on the line is PLC controlled. When the welding current or voltage is out of the rated range, the welding power supply signals the PLC, which in turns sends the signal to the control cylinder. There, the product will be determined to be unqualified, and will be transferred out of the system. The machine also carries out 100% opening and closing temperature calibration, as well as NG sorting.

Laboratory

Based on the motor parameters, we carry out experiments to determine the best thermal protection and control solutions for your needs. These tests include high and low temperature tests, hot and cold impact tests, vibration tests, and life tests, and are all carried out in our laboratory.