- Home

- Products

- Thermal Overload Relay / Motor Thermal Protection Switch

- 17AM-D Motor Thermal Protection Switch

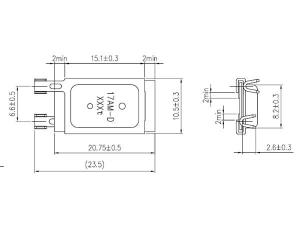

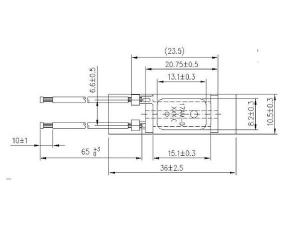

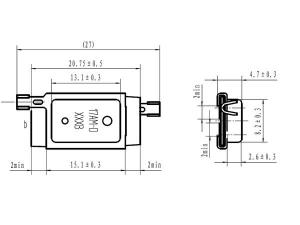

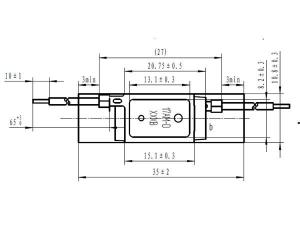

17AM-D Thermal Overload Relay / Motor Thermal Protection Switch

The thermal overload relay / motor thermal protection switch is designed with reasonable structure, compact size, large-capacity contacts, and long service life. Temperature of each bimetal has been calibrated precisely. The tripping temperature of the thermal switch ranges from 50℃ to 170℃, in increment of 5℃. Every year, about 75 million sets of 17AM-D thermal overload relays are produced in Changsheng.

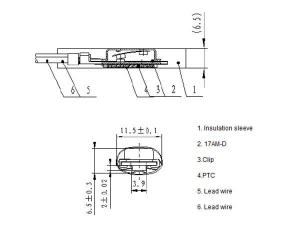

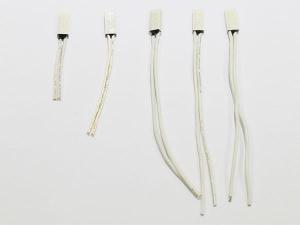

Classified by appearance, 17AM-D series thermal protector is available in type A and type B. For type A, the 2 crimping terminals are at the same side, and that of type B are at two separate ends. All of our thermal protection devices have passed UL, VDE, CE, KC, CB, and CQC certificates.

A PTC Heater is electrically located across the contacts of the 17AM-D. Once activated in a fault condition, it will maintain its open state until power is removed. No reset button, here-simply remove power, the device will cool and reset. This inherent design adds an extra lever of security over automatic reset devices and yields test agency classification as a manual reset device. It is reliable, cost effective solution for numerous applications, like vacuum cleaner motors, remote location motor, submersible pump motors, fractional horsepower motor, mixer and blending motor, electrical tooling, and battery chargers.

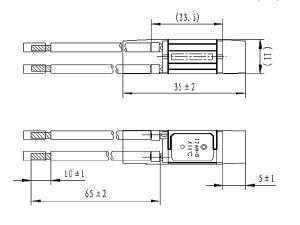

Thermal overload relay drawingsSalient Features

1. Max contact capacity: 16A/125VAC (6000 times of service); 8A/250VAC (6000 times of service); 24VDC/20A (10,000 times of service)

2. The contact resistance of the thermal overload relayis no more than 50mΩ (the contact resistance value initially shown on milliohmmeter)

3. In normal conditions, the insulation resistance between wires and insulating sleeve should be over 100MΩ (tested with DC500V megger under room temperature)

4. According to clients' requirements, we can equip the thermal reset switch with bimetal strips of different resistivity to reach different tripping time.

5. Standard lead wire: UL3321, UL3398, UL1015, and 65mm, etc.; wire color: white, black, blue, brown, yellow, etc.

6. The bottom of protector casing is made from galvanized sheet, so generally we will prepare heat-shrinkable Mylar insulating sleeve for the protector. Standard sleeve is 38mm long. Besides, we can provide different materials of insulating sleeves with special length and thickness upon clients' request.

7. Seal performance: be submerged in hot water (>85℃ but less than boiling point) for 5 seconds, no continuous bubble.

8. Material information: RoHS REACH compliant and test report will be provided upon your request.

| Model | Opening temperature | Closing temperature | Model | Opening temperature | Closing temperature |

| 50±5℃ | 35±15℃ | 115±5℃ | 75±15℃ | ||

| 55±5℃ | 35±15℃ | 120±5℃ | 75±15℃ | ||

| 60±5℃ | 45±15℃ | 125±5℃ | 80±15℃ | ||

| 65±5℃ | 50±15℃ | 130±5℃ | 85±15℃ | ||

| 70±5℃ | 50±15℃ | 135±5℃ | 85±15℃ | ||

| 75±5℃ | 55±15℃ | 140±5℃ | 90±15℃ | ||

| 80±5℃ | 55±15℃ | 145±5℃ | 95±15℃ | ||

| 85±5℃ | 60±15℃ | 150±5℃ | 95±15℃ | ||

| 90±5℃ | 60±15℃ | 155±5℃ | 100±15℃ | ||

| 95±5℃ | 65±15℃ | 160±5℃ | 105±15℃ | ||

| 100±5℃ | 65±15℃ | 165±5℃ | 110±15℃ | ||

| 105±5℃ | 70±15℃ | 170±5℃ | 115±15℃ | ||

| 110±5℃ | 70±15℃ |

Changsheng is a leading motor bimetal thermal protector manufacturer and supplier, offering various thermal switching products to meet many electric motor thermal overload protection needs. Our company offers a wide range of motor protector, water pump protector, light fixture protector, and the thermal protection products have passed many certificates like UL, VDE, KC, CE, CQC.

Index

Induction Motor Thermal Switch, Thermal Protector

Ballast Protector, Vehicle Motor Thermal Protector

Vacuum Cleaner Component, Electric Tool Parts

Pump Motor Relay

Jiangsu Changsheng Electric Appliance Co., Ltd.

Tel.: +86-519-85920008